Easy Traceability | EMEA

Optimize traceability in dicing processes with a code reader

Conventional wisdom is that achieving traceability requires added time, effort, and costs

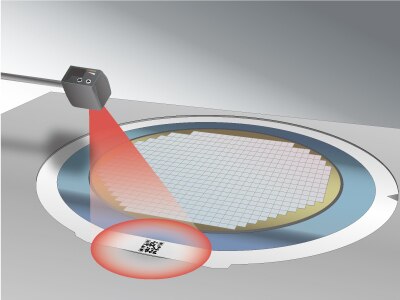

Traceability at semiconductor manufacturing sites is an extremely important issue. One method for achieving traceability in the dicing process is by affixing 1D or 2D codes to the frames that securely hold wafers as they are sliced off on-by-one into IC chips.

However, in order to accurately read these codes with a conventional code reader, adjusting the position and angle requires additional time and effort. It may be necessary to install extra lighting to reduce or eliminate the impact of reflections from surrounding light sources , resulting in increased costs and man-hours.

Design engineers who specialize in semiconductor production equipment manufacturing are constantly considering how to reduce the time and effort involved code reader installation and adjustments.

An easy way to achieve traceability: a compact, high-resolution, low-cost code reader

Previously, the variety of code readers that could be installed on semiconductor production equipment was limited by user needs to save space and the resulting lack of available installation space. Semiconductor production sites need code readers with strong performance that are also compact.

IDEC's solution to meet the sophisticated needs of semiconductor production equipment manufacturers was the WB2F 2D code reader.

The WB2F was compact, with a 24mm length, 40mm width and 32mm depth. It featured a 1.2 megapixel CMOS image sensor with high resolution, excellent specifications for installation on dicers. The auto-tuning function provided easy reading adjustment to save time. At a comparatively low price point, the WB2F gave users the opportunity to introduce the code reader at their facilities at a relatively reduced cost.

With conventional code reader, reflections and a low contrast ratio can make parts marking and code scanning more difficult on certain materials (e.g. metals), leading to read errors. The WB2F's auto-tuning function had the ability to eliminate these errors. Even if an error did occur, the cause could be identified from the high-resolution saved images and immediately acted on.

IDEC's compact products and solutions: ideal for equipment integration

The WB2F fixed 2D code scanner is just one example of a compact IDEC product designed for installation within semiconductor manufacturing equipment. We develop and create products that can be used effectively within limited space constraints, helping customers to create a traceability environment with dicers or any other semiconductor manufacturing equipment.

Please contact us for more detailed information on our solutions for the semiconductor manufacturing industry and installation best practices.

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.