Easy Switch Replacement | EMEA

Quickly and easily replace switches without prolonging downtime

Significantly reduce maintenance time

Loosening and tightening screws with a screwdriver increases the workload

At semiconductor manufacturing sites, preventing downtime is a key priority when aiming for throughput that maximizes production efficiency.

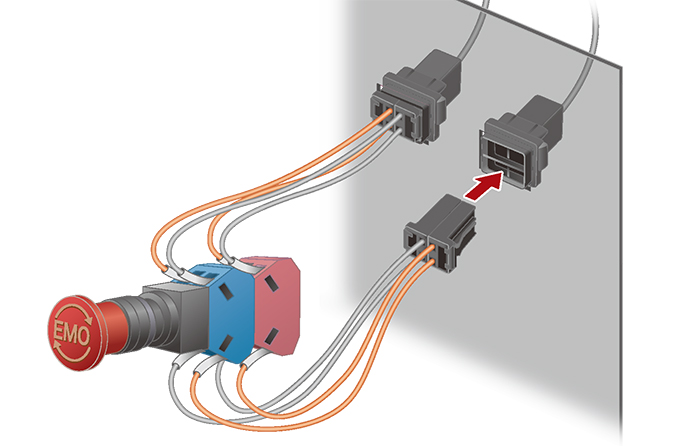

However, no matter which countermeasures are implemented, equipment must be stopped temporarily during maintenance for parts replacement. As an example, wiring maintenance often requires removing the screws with a screwdriver, changing the wiring, and then using the screwdriver again to secure the screws back into place.

Loosening and tightening multiple screws one by one in this way is a time-consuming task.

In addition, designers of semiconductor manufacturing equipment must meet the conflicting end user demands for miniaturization and the continued need to fit a screwdriver inside the equipment. This only serves to increase the difficulty of the design process.

Reduce downtime with quicker and simpler switch replacements

What can be done to speed up the switch replacement process and meet the demands for more compact equipment?

For equipment design engineers, IDEC offers smart solutions. Our switch solution uses a wiring harness to drastically reduce wiring time. By attaching a male connector on the wiring side and a female connector on the terminal block side (previously a screw mount), the wire can be quickly attached and removed even in tight spaces. This design for switch wiring reduces the burden on equipment designers, and cuts downtime during parts replacement work.

Contact IDEC for switch-related solutions suited to your application

IDEC understands the requirement of semiconductor manufacturing devices ensuring our customers total support from drawing switch parts, quality control, to delivery. We can customize products to meet customer demands such as cable length adjustment and switches with connectors. We can also support customers regarding system solutions such as using connectors for wiring switches and single board mounting. Contact IDEC if you have any concerns about switches.

We understand the specific needs and requirements in semiconductor manufacturing, and offer customers comprehensive support. We handle everything from switch component design to quality control and delivery. We can also offer customizations that meet specific customer needs, such as cable length adjustments and pre-connected switch components, and advice on installation of multiple switches.

For system-related consultations, please get in touch with your regional IDEC team.

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.