Stay ahead in food production safety: the IDEC KW2D RFID reader for precise worker traceability and accurate data-logs

Date: 14/08/2025 | By: IDEC HQ

Loading...

When you think of ‘traceability’ in food supply chains and production, you may think of the food itself. People want to know where their food comes from, and the journey that it took to reach their plate.

If you work in food production, you’ll also want key information about the workers who helped that journey happen.

There are food safety risks at every stage of the supply chain. As food products move along conveyor belts and between processing facilities, inspections and quality controls help to prevent defects and other issues.

Under many food safety regulations, keeping comprehensive records of these checks and inspections is mandatory. The global food manufacturing industry is under constant pressure to maintain the highest levels of safety and hygiene, and to comply with laws and regulations.

RFID systems – such as the IDEC KW2D – offer a centralized, real-time solution for worker traceability and record keeping.

RFID systems and their applications in manufacturing: the basics

RFID stands for ‘radio-frequency identification’. RFID readers send out an electromagnetic pulse (radio waves) to identify nearby RFID tags.

The radio wave frequency often used for RFID tags embedded in keyfobs and contactless cards – common access methods at factories, warehouses and other manufacturing facilities – is 13.56MHz.

Every tag has a unique ID code (UID), which is set during production. Tags contain other identifying data, such as the holder’s name and authority level, which can be set and changed using software.

In industrial settings, RFID systems can be used to efficiently record and manage:

Entry/exit times (start/finish times)

Access to areas and equipment

Use of tools and materials

Operational restrictions (user authority)

Settings changes

Inspection history

etc.

Added worker visibility in environments that demand protective equipment

In many industries, including food production, inspections must be carried out by a “qualified person” – a formally named representative, and/or someone with recognized qualifications. As such, workers with the authority to inspect certain items need to be uniquely identifiable.

Using biometrics and other facial/visual recognition can be difficult in food production facilities. Workers must wear protective equipment such as face masks, hair nets, goggles and gloves. This equipment is essential for food hygiene – but also makes traditional identification methods, such as checking ID cards, ineffective.

In these situations, manufacturers need another way to be sure the appropriate person has done the necessary work.

RFID tag data is separate to the holder’s appearance – workers can easily be identified even when fully covered.

The identifying data includes the holder’s authority level, so the RFID reader can instantly confirm that person’s credentials on detecting the tag. This also enables user-specific customization of control options on a connected HMI display.

How RFID supports worker traceability and inspection history management

To register their work history, employees simply hold their ID card or keyfob up to the reader. Every time the RFID reader detects a tag, it registers the UID, the holder’s authority level, and the verification result.

When used to create inspection history logs during food production processes, RFID system records can show you:

When an inspection took place

Who carried out the inspection

How long the work took to complete (start and finish times)

The number of days since the previous inspection

Whether more than 1 inspection took place on the same day

Whether anyone else attempted to access the area/equipment

These time-stamped records can be transmitted to a host controller.

Digital records have the added benefit of bridging physical gaps between work locations and different stages of the production process. With data collected and transmitted almost instantly, everyone has the latest information at any given time. Safety, quality, and traceability levels can be increased across all work sites.

IDEC supports the food production industry with safety and security solutions

The IDEC KW2D RFID reader has both the features needed for inspection history management and for reliable use in food production environments:

Easy installation: designed for mounting on metal surfaces

Dedicated software: easily adjust tag and reader settings

Credential control: customize up to 500 tags with up to 255 authorization levels

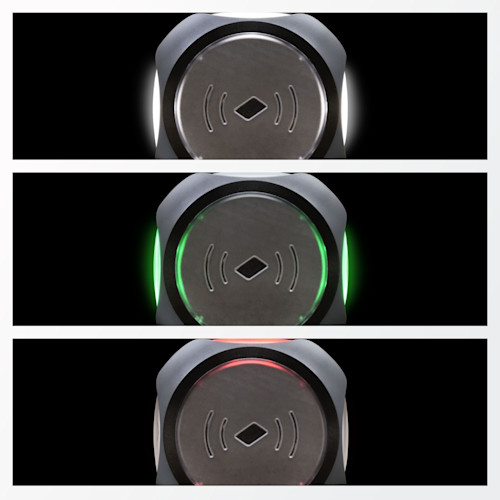

Visible/audible feedback: white/green/red LEDs and a buzzer

Added authentication layer: recognizes IDEC tags

Ethernet connectivity: for use with touch panel HMIs and PLCs

IP65/IP67 rating: highly resistant to water, dust, and oil

Find out more about the KW2D here on the IDEC website.

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.