Robot Safety Switches | USA

Safe collaborative work with just one switch in work environments without safety fences

The new keyword: human-robot "collaboration"

"Collaboration" between humans and robots has rapidly become a keyword for improving productivity at automotive manufacturing sites.

The current trend is to automate all production processes, so that robots perform the work previously done by humans. Even so, there are still some processes that are difficult for robots to perform. Robots are great for simple work processes, transporting heavy parts, and similar basic tasks, but human workers are still more appropriate for tasks requiring careful attention such as installing seats. As such, the idea that dividing work procedures between humans and robots would serve to improve productivity was born. However, this results in the issue of ensuring safety.

Safety is conventionally maintained with the installation of safety fences to keep robots and humans separated. In contrast, collaborative work cannot be performed unless the safety of work environments can be ensured without fences.

Collaborative work, with robots intentionally moved by humans, improves productivity

There is a way to maintain safety while maximizing the benefits of automation.

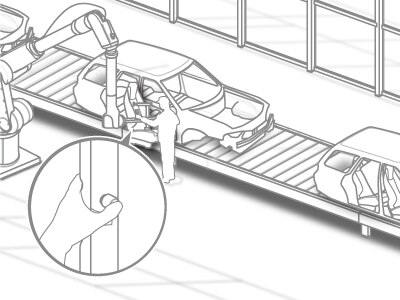

IDEC recommends 3-position enabling switches for carrying out safe human-robot collaborative work. Using these enabling switches allows you to create a system in which a robot only moves when the switch is lightly pushed by a human in an intentional manner. The robot stops when the operator removes their hand from the switch or grips it more tightly, due to spontaneous movement from sensing danger or similar perceived risk.

This means that the robot moves only when consciously directed to by a human in the work environment, using a 3-position enabling switch. This system helps to maintain the safety of workers near the robot. In addition, you can install a safety laser scanner on the robot to serve as a presence detection sensor, so that high-speed operations can only be performed when no workers are in the operating range of the robot.

Taking the process for installing seats in a car body as the example, a robot can rapidly move the heavy seat to the installation position and then stop right next to the car body. Next, the worker can press the enabling switch on a hand guidance device attached to the robot arm, and accurately install the seat. Using 3-position enabling switches as part of robot hand guidance in this way allows for smooth operations during multiple processes, and enhances automation to further improve efficiency.

Select the enabling switch that meets your needs from our large and varied lineup

IDEC enabling switches are compliant with the international safety standard IEC 60947-5-8, and are designed with full consideration of both safety and ergonomics. Choose the product that best suits your work environment from our diverse lineup.

We can provide consultations and offer suggestions for enabling switches and for human-robot collaborative work. Please feel free to contact us if you have any questions or concerns on these topics.

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.