Smart Screen Updates | USA

Make effective use of AGVs and build highly functional factories that use smart, efficient screen updates

Time and labor involved in screen updates lowers productivity

Automated guided vehicles (AGVs) are used to deliver various parts to different areas of factories. As demand for smaller AGVs remains strong, to make effective use of limited factory space, we have seen more compact operator interfaces installed on AGVs as displays and control terminals.

However, it takes a significant amount of time to update the displays on small operator interfaces that have been installed on AGVs. This is due to display issues and failures, changes to production line layouts, and other factors. A key reason is that these operator interfaces do not have the network functionality for updates that larger-scale display devices are designed with as standard.

When AGV manufacturers receive layout (system) change requests from manufacturers, they typically need to develop the new display, then visit the factory in person. Only then can they manually make changes, using a wired connection to link a computer they brought with them to the operator interface. This process is possible if the factory is in a convenient and easily accessible location. If the customer is a global corporation and they have factories across the globe, it is much more difficult for AGV manufacturers to visit every single client factory to perform maintenance.

Compact operator interfaces with wireless communication capabilities for easy screen updates

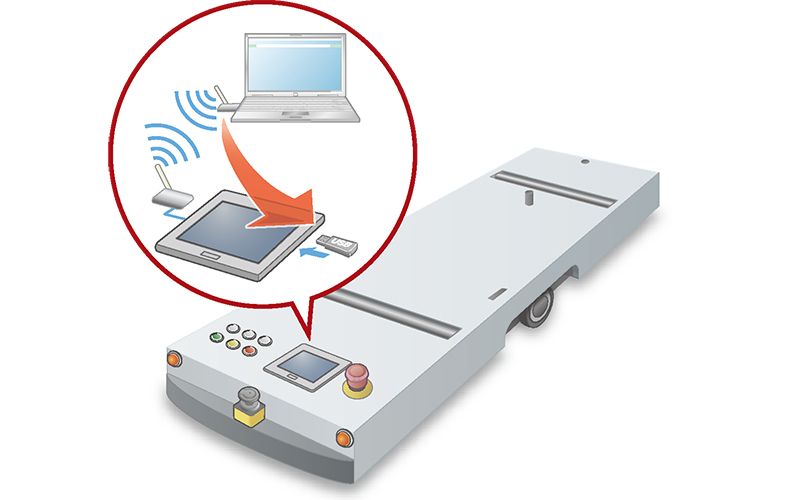

The IDEC HG1G operator interface can solve many of the issues that AGV manufacturers and end users face.

The HG1G has a compact 4.3-inch display and comes with FTP server functionality. This feature enables files to be transferred via the server, making screen updates via a network simpler. Connect a USB memory device and wireless unit to the HG1G for simple operation. The manufacturer can create new project data using the wireless network, and send (save) it to the USB device via the FTP server function. On the factory side, a maintenance worker can press the 'update' button displayed on screen to complete the changes. The button can also be pressed remotely from a computer, thanks to the web server functionality.

With this high functionality, there is no need for a representative from the manufacturer's side to visit the customer factory in person. Display updates, changes to production line layouts, and ongoing maintenance become quicker and simpler. Users can also expect increased productivity, no matter how many global sites they operate.

IDEC operator interfaces with strong performance and flexibility

The HG1G is an ideal HMI for the IoT/IIoT era. Thanks to the built-in FTP server functionality, the project data for screen updates and history logs can be transferred and accessed from anywhere. As the HG1G gives users remote access and control from computers and mobile devices, it is easy to check the current status and take action in an emergency.

Please get in touch with your regional IDEC team for advice on HMI solutions for factories and the ability to remotely monitor and control displays, AGVs, and other machines and equipment.

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.