Production Site Robot Collaboration | USA

Use a third-party risk assessment to reduce risk at human-robot collaborative production sites

Do you have concerns about safety at collaborative production sites where humans and robots work closely together?

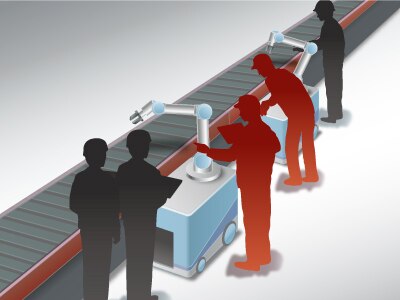

Safety in collaborative work spaces

The number of production sites where humans and robots collaborate (work together, in the same environment) continues to rise. As robots represent an inherent source of danger to humans, a thorough risk assessment and appropriate safety measures must be implemented before humans can enter the work area.

When bringing collaborative robots into an industrial work environment, the risk assessment and selection of safety measures must start from the design and build of equipment used in work processes. Production engineers and designers who are familiar with each work process and with ensuring safety often manage equipment installation in collaborative spaces. However, this does not reduce the possibility of workplace accidents to zero.

Many production engineers and designers are likely to consider involving a third part in their risk assessment, in order to assess and improve the safety level as far as possible.

IDEC offers industrial safety measures and advice from qualified Safety Lead Assessors

At IDEC, we understand that many customers want to maximize safety at production sites where humans and robots work closely together, and to reduce risks as far as possible.

The IDEC team includes a substantial number of qualified Safety Lead Assessors (in Japan). They can consult on safety and support customers in implementing safety measures based on international safety standards.

When an IDEC employee with Safety Assessor certification carries out a risk assessment at a customer site, they will survey the site alongside the production engineer/designer and comprehensively identify risks. Where risks are found, the Safety Assessor will propose appropriate countermeasures from their perspective as a safety professional.

IDEC supports a wide range of global corporations in improving and maintaining safety, and offers a varied lineup of safety products. In addition, we encourage our employees to study for and achieve Safety Assessor, Safety Lead Assessor, and Robot Safety Assessor qualifications. We are committed to strengthening safety knowledge within our workforce.

We have established a technical center for collaborative robots, where we propose usage methods, safe system building practices and Collaborative Safety solutions to customers considering introducing industrial robots at their work facilities.

If you have any questions or concerns about system building, equipment design, risk assessments, or anything else relating to industrial safety measures, please feel free to contact us.

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.