Intrinsic Measures | India

Implement essential measures to minimize the risk of explosions

Prevent explosions with accuracy by eliminating potential sources of ignition

Conventional measures cannot completely eliminate the risk of explosions

In semiconductor manufacturing, where hazardous chemicals and gases are used on a regular bases, manufacturers implement various safety measures for each piece of equipment. You may be aware of this - but not that, in the face of these measures, the risk of explosions at semiconductor manufacturing sites is not reduced to zero.

Highly flammable gases such as hydrogen, propane and arsine are used in these manufacturing processes. One conventional way to prevent explosions is to fill the equipment with nitrogen to prevent arcing (a type of gas discharge). This may seem like a sufficient safety measure, yet it is not guaranteed to prevent an explosion.

With the conventional nitrogen filling method, if the filling mechanism malfunctions this may create an explosive atmosphere. The risk of an explosion cannot be completely eliminated in this way.

Given this, how can appropriate explosion-proof measures and systems be implemented at semiconductor manufacturing sites?

Intrinsically safe explosion-proof measures are essential to eliminate the risk of explosions

There are 3 things needed for an explosion to occur: a flammable gas, a gas that supports combustion (e.g. oxygen), and an ignition source.

To put this another way, if any one of these factors can be completely eliminated from the environment then it becomes possible to intrinsically prevent explosions.

As eliminating oxygen from a semiconductor manufacturing environment is extremely difficult, the most realistic method is to eliminate ignition sources.

IDEC has over 7 decades of experience in researching and developing explosion-proof technologies. We offer intrinsically safe, explosion-proof relay barriers that use low-level currents - a low enough level that they cannot cause ignition.

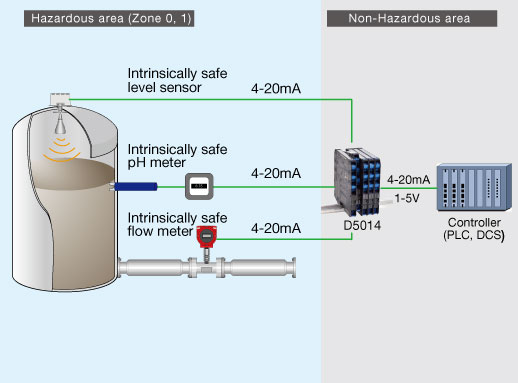

In equipment used in an explosive atmosphere, the wiring that transmits information from sensors and safety devices to the controller is seen as the main ignition source. Lowering the current or voltage and keeping it below a certain level prevents the wiring from becoming a source of ignition, preventing explosions.

IDEC relay barriers take the weak signal received from hazardous areas with explosive atmospheres and amplify that signal in a non-hazardous area. By doing so, the information can be transmitted to the controller without risking or causing an explosion.

Our expansive explosion-proof product lineup and history of results ensure we can provide generous support

Intrinsically safe, explosion-proof products from IDEC are typically smaller, lighter, and more cost effective than other similar explosion-proof devices. They also support digital and analog inputs/outputs, making it easier for systems designers and engineers to plan and design sensors, switches, and other devices to be used in hazardous areas.

We have a long track record of supporting customers in implementing explosion-proof measures in their work environments. Please contact us for advice on the most suitable products for your application, and design and planning tips to help prevent damage and harm caused by explosions.

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.