Smart Blind Spot Safety | Canada

Safety is maintained with surface detection sensors that never miss the presence of a person or forklift

Conventional safety measures cannot completely prevent human injury

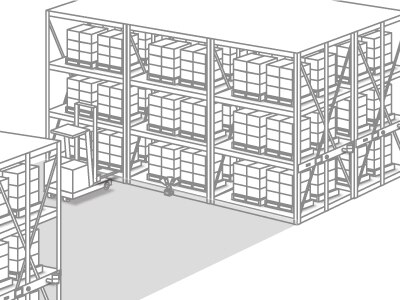

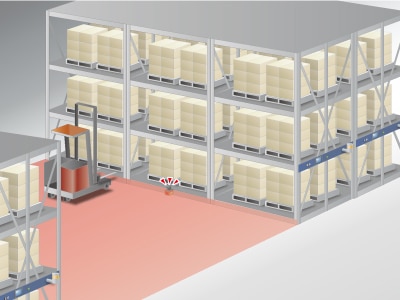

It is common to use movable electric racks for warehouse storage, especially in confined spaces. In these cases, forklifts are typically used to load and unload the items. It may sometimes be necessary for humans to move in between the racks to carry out cleaning and maintenance. To prevent accidents, the racks are equipped with safety measures.

Conventional safety measures include photoelectric sensors for linear presence detection, and safety bumpers that activate whenever a human or forklift comes into contact with them to stop the racks. However, these measures still have "blind spots" where detection with sensors is difficult or impossible. There are also cases where someone other than a worker has mistakenly operated the racks, resulting in human injury.

Just one scanner capable of surface detection reduces accidental operation of racks to zero

How can users of movable racks achieve both safety and productivity? At IDEC, we use our many years of experience in safety measures for various industries to offer suitable solutions. Our recommendation is the SE2L Advanced safety laser scanner.

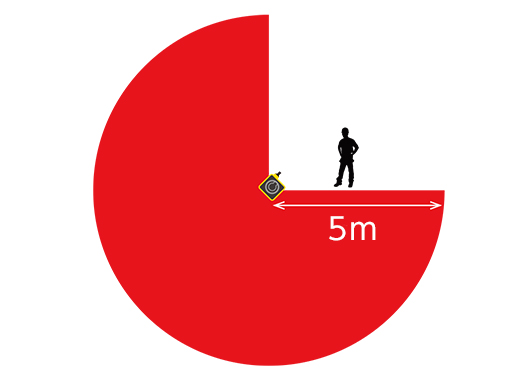

The SE2L Advanced is capable of surface detection, and has a maximum 5-meter detection distance across a 270-degree sensing radius. By installing a single scanner near the center of the rack, it becomes possible to easily detect humans and forklifts from various angles.

Using this safety laser scanner helps to prevent accidental rake operation and resulting accidents and injuries.

Prevent unintentional machine stoppages caused by dust and dirt

Conventional photoelectric sensors may detect dust and dirt as nearby presences, stopping operation of the racks. The SE2L Advanced has a feature that uses the signals received to identify dust and dirt, preventing unintentional machine stoppages.

As this feature continues to reliably identify dirt and dust particles in polluted environments, it contributes to operational efficiency at warehouses.

Rely on IDEC's support to create safe production sites

As specialists in safety measures, at IDEC we are dedicated to ensuring safety in a wide variety of industries. Alongside the SE2L Advanced safety laser scanner introduced on this page, we offer a wide variety of products and solutions for production site safety. Please get in touch whenever you have questions or concerns about safety measures.

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.