FT2J Series

Date: 27/10/2024

Loading...

7” FT2J Series Combined PLC + HMI

A technologically advanced 7” vivid multi-touch display, with an integrated PLC controller and expandable I/O, makes the new FT2J Series a leading choice for many applications across a wide variety of industries.

A wide operating temperature range of -20°C to +55°C as well as IP66F, IP67F, Type 4X, 12, 13, and Class I Div 2 approval ratings, assures reliable operation in the toughest environments. These touchscreens are built for endurance and are backed by an industry-leading three-year warranty.

Highlights

Combining a PLC and touchscreen HMI interface into a single platform provides many advantages for monitoring and controlling smaller machines, process skids, and HVAC systems.

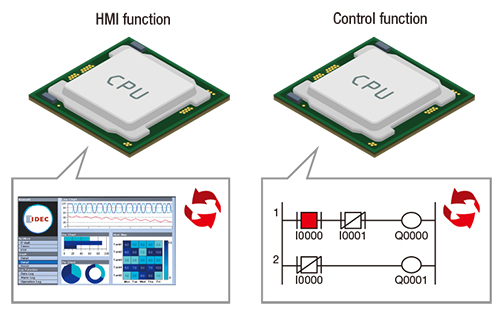

Dual CPU Configuration

The FT2J features two CPU's working in parallel for the PLC and HMI. This design enables high-speed, real-time control without compromising HMI functionality, broadening the range of compatible applications.

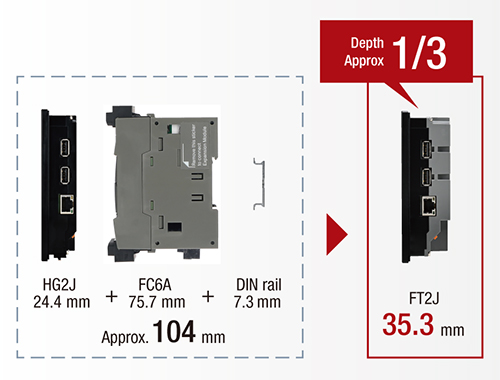

One Compact Design

One PLC + HMI consumes less panel space than separate units.

Simplified Installation

A combined PLC+HMI minimizes wiring time because no connections need to be made between the PLC and HMI, a single power source powers both the PLC and HMI, and only one network connection needs to be made to the outside world. Plus, push-in type power connector is used for providing easy installation and service.

Streamlined Programming

The combined PLC+HMI unit tightly integrates the PLC and HMI programming into a single suite of software which cuts configurations and programming time, and the PLC+HMI is ready to use and communicate right out of the box.

Advanced PLC Control Capabilities

With built-in full function controller features and functions, both onboard and expandable I/O, the FT2J Series comes with built-in analog inputs/outputs and enhanced PLC features, including PID, PWM control, script programming and much more.

I/O expansion with cartridges

Up to 2 digital I/O cartridges or analog I/O cartridges can be connected to add up to 8 digital I/O, and up to 4 analog I/O.

Analog I/O

Equipped with a built-in analog I/O to control analog signals from 0 to 10V DC (4 to 20 mA) with 12-bit resolution. An analog potentiometer connected to the analog input allows for easy configuration of analog settings, such as a timer.

PID Control

PID algorithm is used to enable cascade control. Available for applications requiring temperature, flow, and pressure control.

Intuitive Touchscreen Interface

The HMI’s projected capacitive touch panel (PCAP) advanced technology—saves space while providing a smaller footprint and improves performance. This PCAP touch panel provides a high degree of visibility, durability, and functionality. In addition to being multi-touch, this PCAP touch panel is compatible with thin gloves.

Highly visible glass-top structure

Easily kept clean using chemical washdown or simple wipes. Besides being water- and scratch-resistant, PCAP is responsive and provides a high tolerance to resist false signals when dirt or water droplets are present on the face of the HMI.

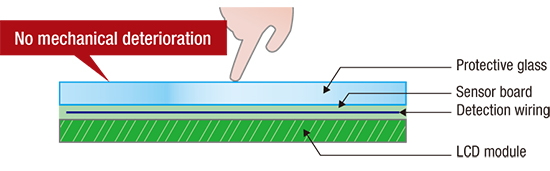

No mechanical durability issues

The PCAP touch panel uses a sensor board to detect changes in electric charge to identify the position of the touch.There is no mechanical deterioration allowing for agile operation and multi-touch sensing gloves less than 1.5mm thick (*1) can be used.

*1) The touchscreen may not work with gloves thicker than 1.5mm, depending on the material of the gloves and the environment.

Industrial Grade HMI Design

Extreme Operating Temperatures<br>

-20 to 55°C.Long LED Backlight Life<br>

Industry leading 50,000 hours of backlight life.Low Maintenance<br>

Battery-free MRAM and hyper-capacitor design eliminates the need for battery-replacements.Reduced Power Consumption<br>

Consume approximately 40% less power than separate PLC and HMI combined.Waterproof/Oil Resistance<br>

IP66F and IP67F ratings make these units suitable for wash-down applications and subject to oil spills.Industry Leading Warranty<br>

Built for endurance and backed by a three-year warranty.Certifications<br>

UL61010, UL Type 4X, 12, and 13, Class I Div 2 for hazardous locations.Large User Memory<br>

24MB (screens), 96KB (ladder code).

Environmentally-Friendly

Coin cell batteries not required

Battery-free design with data stored on nonvolatile magnetic media. Time information is preserved with power from large-capacity capacitors. Since lithium batteries are not consumable, they are not affected during ocean and air transportation and do not require maintenance for battery replacement, leading to reduced waste.

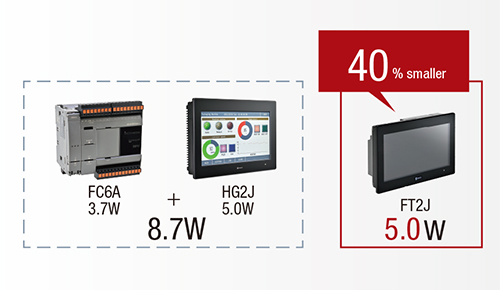

Reduced power consumption

FT2J consumes approximately 40% less power than PLC and display combined*

*) Compared with equivalent models FC6A-C24R4CE and HG2J-7UT22TF-B.

Seamless Communication with Various Devices

Remote I/O System

The SX8R Bus Coupler Module offers an ideal solution for addressing the limited I/O points on the FT2J PLC+HMI unit. By integrating the SX8R, you can effortlessly expand your I/O points using major open network protocols such as EtherNet/IP, Modbus TCP, or CC-Link IE Field Basic. This flexibility ensures seamless connectivity and scalability, allowing your system to adapt to increasing demands and enhancing overall operational efficiency.

Our SX8R Bus Coupler offers the perfect blend of versatility, reliability, and performance, making it the ideal choice for industrial automation applications of any scale. Whether you're upgrading existing systems or building new installations, our Bus Coupler provides the connectivity and flexibility you need to succeed.

An exceptionally wide operating temperature range of -20 to +60 ˚C as well as IP20, and Class I Div 2 approval ratings, assures reliable operation in the toughest environment. This SX8R Bus Coupler is built for endurance and are backed by an industry-leading three-year warranty.

Experience seamless integration and enhanced efficiency with our Bus Coupler. Learn More

We provide a wide range of help and resources:

If you have questions or suggestions, we're here to listen.

Our sales and support teams are on hand to help.

All the technical documentation you need.